Microfluidics is a field that focuses on the controlled handling of very small volumes of fluids, often at the scale of microliters or smaller. Polymer devices play a central role in microfluidics because they provide practical materials for fabricating channels, chambers, and interfaces that guide fluid movement with precision.

Polymer-based microfluidic devices exist because early microfluidic systems relied heavily on rigid materials that were difficult to process, adapt, or scale for diverse applications. Polymers introduced flexibility in design, easier fabrication methods, and compatibility with a wide range of experimental and analytical needs.

These devices are typically made from materials such as elastomers, thermoplastics, or other polymer compounds. Their properties allow researchers and engineers to create complex micro-scale structures that support fluid control, mixing, separation, and analysis. Understanding this context explains why polymer devices have become foundational components in modern microfluidic systems.

Why Polymer Device Use Cases Matter

Polymer device use cases matter because microfluidic technologies are increasingly applied across science, healthcare research, diagnostics, environmental testing, and industrial analysis. The material choice directly influences device performance, reproducibility, and application scope.

This topic affects:

-

Researchers developing lab-scale analytical tools

-

Engineers designing compact fluid-handling systems

-

Academic institutions and research laboratories

-

Technology teams working on diagnostic platforms

Key challenges that polymer devices help address include:

-

Complex fabrication requirements of rigid materials

-

Limited adaptability of traditional micro-scale components

-

Difficulty integrating multiple functions into small devices

-

Constraints on rapid design iteration

Polymers enable faster prototyping and more adaptable designs, making microfluidic systems more accessible for experimentation and application development. Their use supports innovation by lowering material and design barriers while maintaining functional reliability.

Common Polymer Materials Used in Microfluidic Devices

Different polymers are selected based on their mechanical, chemical, and optical properties. Each material supports specific microfluidic functions.

Elastomeric polymers

These materials are flexible and allow reversible deformation. They are often used where valves, pumps, or dynamic channel control is required.

Thermoplastic polymers

Thermoplastics provide structural stability and are suitable for rigid channel designs. They are often chosen for durability and dimensional consistency.

Biocompatible polymers

Certain polymers are selected for compatibility with biological samples. These materials support applications involving cells, proteins, or sensitive reagents.

The table below summarizes common polymer categories.

| Polymer Category | Key Property | Typical Use Case |

|---|---|---|

| Elastomers | Flexibility | Valves and pumps |

| Thermoplastics | Rigidity | Fixed channel systems |

| Biocompatible Polymers | Sample safety | Biological analysis |

Key Use Cases of Polymer Devices in Microfluidics

Polymer microfluidic devices are applied in a wide range of contexts. Their versatility allows them to support both experimental and applied systems.

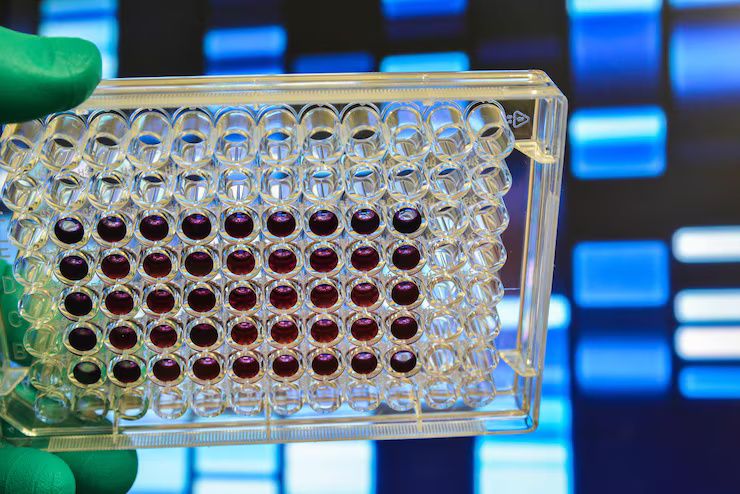

Analytical testing and assays

Polymer devices are used to conduct chemical and biochemical assays with minimal sample volumes. Microchannels enable precise reagent handling and reaction control.

Biomedical research

In research settings, polymer microfluidic platforms support studies involving cells, tissues, and biomolecules. Their transparency and adaptability aid observation and analysis.

Point-of-analysis diagnostics

Compact polymer devices allow integration of multiple analytical steps into a single platform. This supports streamlined testing workflows in controlled environments.

Environmental monitoring

Microfluidic polymer systems are used to analyze small-volume samples from water, air, or soil sources with controlled processing conditions.

Educational and prototyping applications

Because polymers allow rapid fabrication, they are widely used in academic settings for teaching microfluidic concepts and testing new designs.

The table below illustrates how use cases align with device functions.

| Use Case Area | Primary Function | Practical Outcome |

|---|---|---|

| Analytical Testing | Controlled reactions | Precise measurements |

| Biomedical Research | Sample handling | Experimental insight |

| Diagnostics | Integrated workflows | Compact analysis |

| Environmental Studies | Sample processing | Localized testing |

| Education | Rapid prototyping | Concept demonstration |

Design Advantages of Polymer-Based Microfluidic Devices

Polymers provide several design advantages that support diverse microfluidic applications.

Key advantages include:

-

Ease of molding and patterning

-

Optical transparency for observation

-

Compatibility with multiple fabrication techniques

-

Ability to integrate flexible and rigid features

These characteristics allow designers to create devices with complex channel networks, layered structures, and embedded functional elements without excessive fabrication complexity.

Developments and Shifts in Polymer Microfluidics

Polymer microfluidics continues to evolve as fabrication methods and application needs change. One noticeable trend is the move toward multi-material devices, where different polymers are combined to achieve varied mechanical and chemical properties within a single system.

Another development is increased focus on surface modification. Polymer surfaces are now often treated to control wettability, chemical interaction, or sample adhesion, improving device performance for specific applications.

There is also growing interest in modular microfluidic design. Polymer components are increasingly designed as interchangeable units, allowing systems to be reconfigured without redesigning the entire device. These shifts reflect a broader emphasis on flexibility and functional integration.

Regulatory and Policy Considerations

Polymer devices used in microfluidics are influenced by regulations related to material safety, laboratory standards, and application-specific guidelines. The impact of regulation depends on how and where the devices are used.

Key regulatory considerations include:

-

Material safety and chemical compatibility standards

-

Laboratory handling and disposal guidelines

-

Application-specific compliance for biomedical research

-

Environmental safety rules for polymer materials

Government and institutional policies often define acceptable materials and processes for research and testing environments. Understanding these considerations helps ensure that polymer microfluidic devices are developed and used responsibly.

Tools and Resources Supporting Polymer Microfluidic Development

A range of tools and resources support the design, fabrication, and evaluation of polymer microfluidic devices. These resources focus on technical understanding and workflow support.

Common tools and resources include:

-

Microchannel design software

-

Fabrication process guides

-

Material property reference charts

-

Flow simulation models

-

Device testing and validation templates

The table below shows how these resources support development.

| Tool Category | Purpose | Practical Benefit |

|---|---|---|

| Design Software | Channel layout | Accurate modeling |

| Process Guides | Fabrication steps | Reproducible results |

| Material Charts | Property comparison | Informed selection |

| Flow Models | Fluid behavior | Predictable performance |

These tools help bridge theoretical concepts and practical device construction.

Challenges in Polymer Microfluidic Devices

Despite their advantages, polymer devices also present challenges that must be managed during design and use.

Common challenges include:

-

Material deformation under pressure

-

Surface interactions affecting fluid flow

-

Long-term stability of certain polymers

-

Sensitivity to temperature or chemical exposure

Addressing these challenges requires careful material selection, design optimization, and testing.

Polymer Devices and Integration with Other Technologies

Polymer microfluidic devices are often combined with sensors, optical components, or electronic interfaces. This integration expands their functionality beyond fluid handling alone.

Examples of integration include:

-

Optical detection systems

-

Embedded electrodes for measurement

-

On-chip mixing or separation elements

-

Modular connectors for system expansion

This integration supports more comprehensive micro-scale systems for analysis and research.

Frequently Asked Questions

What are polymer devices in microfluidics?

They are micro-scale fluid-handling systems made from polymer materials, designed to control and analyze small fluid volumes.

Why are polymers commonly used in microfluidic devices?

Polymers offer flexibility, ease of fabrication, and compatibility with various applications.

Are polymer microfluidic devices used only in research?

No. They are also used in diagnostics, environmental analysis, and educational settings.

Do different polymers affect device performance?

Yes. Material properties influence flexibility, chemical interaction, and durability.

Are polymer devices suitable for biological samples?

Certain polymers are selected specifically for compatibility with biological materials.

Concluding Overview

Polymer device use cases in microfluidics highlight the importance of material choice in micro-scale fluid systems. Polymers enable adaptable, precise, and accessible designs that support a wide range of scientific and analytical applications.

By understanding the context, importance, use cases, recent developments, regulatory considerations, tools, and common questions related to polymer microfluidic devices, readers gain clear and factual insight into this field. This knowledge supports informed exploration of microfluidics as a versatile and evolving area of science and engineering.