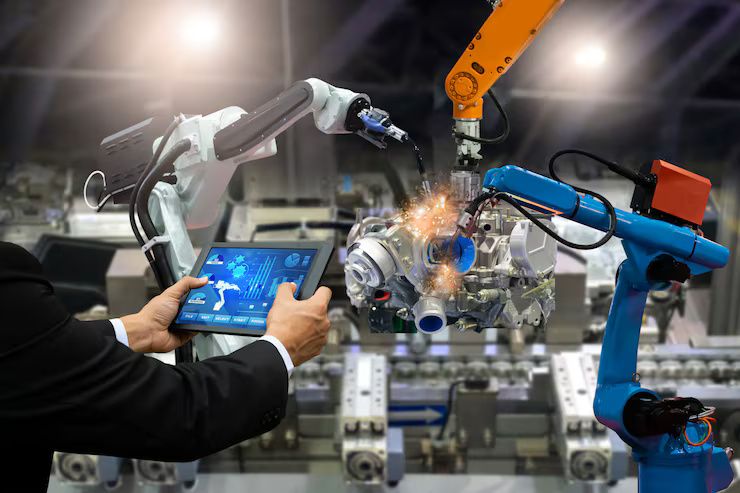

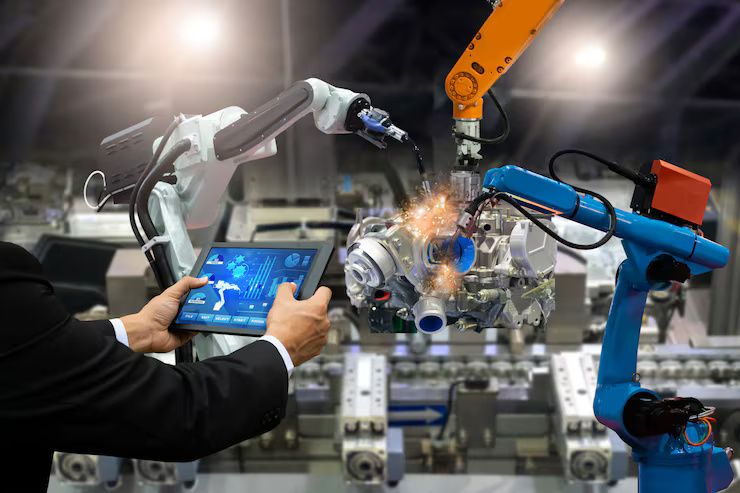

Industrial automation refers to the use of control systems, machinery, and digital technologies to operate manufacturing and industrial processes with minimal human intervention. It exists to improve consistency, precision, and efficiency in production environments where manual operation alone may be limited by speed, accuracy, or safety concerns.

The origins of industrial automation can be traced to the introduction of mechanical control systems during early industrialization. Over time, automation evolved through the use of electrical controls, programmable logic controllers, and computer-based systems. These developments allowed machines to perform repetitive tasks reliably and at scale.

In modern manufacturing, industrial automation integrates hardware, software, and communication technologies. Automated manufacturing systems coordinate machines, sensors, and control platforms to manage production processes from raw material handling to finished product inspection. This approach supports standardized output and predictable performance across various industries.

Importance: Why Industrial Automation Matters Today

Industrial automation has become increasingly important as industries face growing demands for productivity, quality, and adaptability. Global competition and complex supply chains require manufacturing systems that can operate efficiently and respond quickly to changes.

Industrial automation matters today because it:

-

Improves production accuracy and repeatability

-

Reduces human exposure to hazardous tasks

-

Supports higher output with consistent quality

-

Enables data collection for performance monitoring

This topic affects manufacturers, engineers, system operators, and policymakers. Workers benefit from safer environments where automation reduces physically demanding or risky activities. Organizations rely on automated systems to maintain competitiveness and operational stability.

By addressing challenges such as human error, production downtime, and variability, industrial automation helps solve problems related to efficiency gaps and quality control in manufacturing environments.

Recent Updates: Trends and Developments from the Past Year

During 2024 and 2025, industrial automation continued to advance alongside digital transformation initiatives. In early 2024, increased attention was given to smart factory concepts, where machines, sensors, and software systems communicate continuously to optimize production flow.

Mid-2024 saw broader discussion around collaborative automation. Systems designed to work alongside human operators gained visibility, focusing on flexibility and improved human–machine interaction rather than full replacement of manual tasks.

By late 2024 and into 2025, industrial automation discussions emphasized data integration and real-time analytics. Manufacturers increasingly referenced the use of connected systems to monitor performance, predict maintenance needs, and support informed decision-making.

Another notable development has been the emphasis on cybersecurity within automated manufacturing systems. As connectivity increases, protecting industrial control systems became a central topic in automation research and policy discussions during 2025.

Laws and Policies: Regulatory and Standards Framework

Industrial automation is influenced by safety regulations, industrial standards, and national manufacturing policies. These frameworks aim to ensure safe operation, reliability, and responsible use of automated systems.

In the United States, workplace safety guidance related to automated machinery is shaped by the Occupational Safety and Health Administration. These guidelines focus on machine guarding, emergency controls, and worker protection.

Internationally, standards published by the International Organization for Standardization influence the design, testing, and interoperability of automated manufacturing systems.

In India, industrial automation aligns with broader manufacturing and safety initiatives under the Ministry of Heavy Industries. These initiatives support modernization, standardization, and responsible adoption of advanced manufacturing technologies.

Compliance with these laws and standards helps ensure that automation systems operate safely and consistently across different industrial contexts.

Tools and Resources: Learning and Operational References

A wide range of tools and resources support understanding and application of industrial automation concepts. These resources are used in education, system planning, and operational monitoring.

Helpful tools and references include:

-

Automation system design guides and reference manuals

-

Simulation software for modeling automated processes

-

Digital dashboards for monitoring production performance

-

Training materials on industrial control systems

-

Industry publications covering automation trends

The table below outlines common components of automated manufacturing systems and their functions:

| Component | Function | Role in Automation |

|---|---|---|

| Sensors | Detect physical conditions | Data input |

| Controllers | Process signals and commands | Decision-making |

| Actuators | Perform mechanical actions | Physical execution |

| Human–machine interfaces | Display system information | Operator interaction |

| Industrial networks | Enable system communication | Data exchange |

These tools and resources help build foundational knowledge and support effective implementation of automation systems.

Frequently Asked Questions About Industrial Automation

What is the main goal of industrial automation?

The main goal is to improve efficiency, consistency, and safety in industrial processes through automated control and monitoring.

Is industrial automation limited to large factories?

No, automation can be applied in facilities of various sizes, depending on production needs and system design.

How does automation improve manufacturing quality?

Automation reduces variability by following programmed instructions, leading to more consistent production outcomes.

Does industrial automation replace human workers entirely?

Automation often complements human roles by handling repetitive or hazardous tasks while people focus on supervision and decision-making.

Why is data important in automated manufacturing systems?

Data helps monitor performance, identify issues, and support continuous improvement in automated operations.

Conclusion: Industrial Automation in Modern Manufacturing

Industrial automation is a cornerstone of modern manufacturing systems. By combining machinery, control systems, and digital technologies, automated manufacturing systems support efficient, safe, and reliable production.

Understanding the context, importance, regulatory environment, and available resources related to industrial automation helps readers appreciate its role in today’s industrial landscape. As technology continues to evolve, industrial automation remains central to the future of manufacturing and industrial operations.